Automate and Optimize: Replenishment Planning Software for Smart Inventory Control

Maximize constrained inventory, minimize overstock and automate routine replenishment.

Algo’s formula for replenishment planning excellence

Constrained Order Management

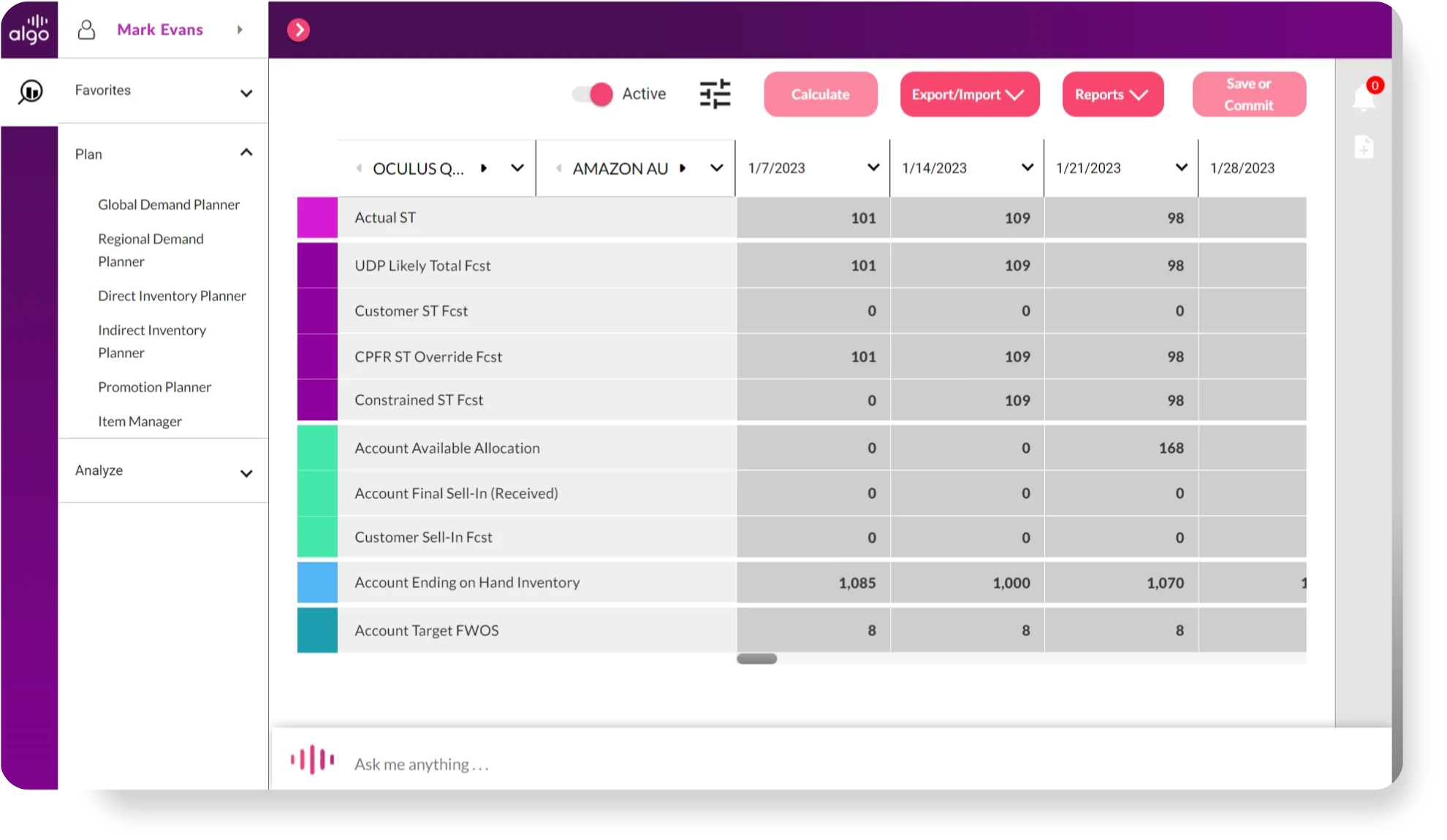

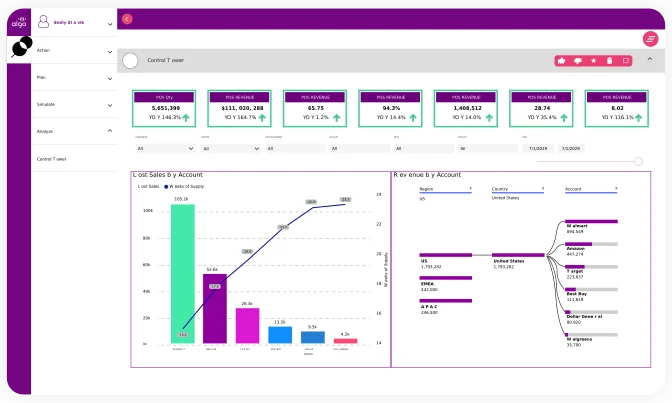

Mitigate risk, optimize receipts, and improve sales KPIs. Algo’s Replenishment Planning solution enables you to instantly run dynamic order management scenarios according to your ever-changing inventory picture. View available inventory, power-rank every item-location combination, and create orders for all your sales channels using a single replenishment tool.

Unified, Cross-Functional Visibility

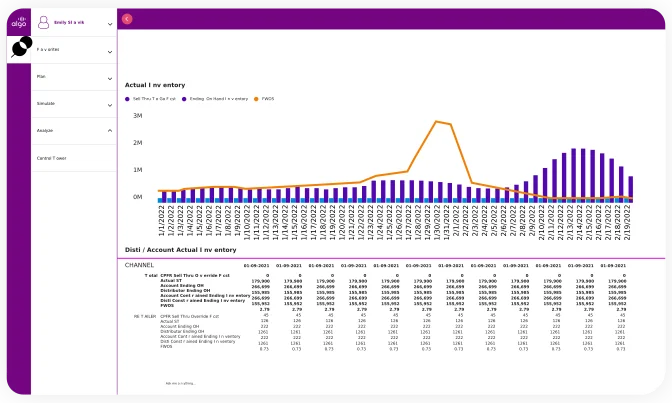

View all the insights you need to make better allocation and replenishment decisions. Algo’s Replenishment Planning solution reduces your reliance on manual spreadsheets to help you focus on business analysis. Its visually rich interface empowers inventory, operations, and logistics teams to collaboratively create, analyze, and adjust replenishment plans.

Agility at Scale

Identify and allocate the right inventory for each location. Algo’s demand-driven replenishment planning software helps inventory operations analysts focus on item-location combinations that require the most attention by reducing the time they spend compiling and managing data. Our advanced analytics enable your team to multiply their productivity by highlighting the biggest opportunities.

Functional and Technical Experts

Algo’s team of functional and technical experts bridges the gap between Operations and IT to provide all the support you need to align our replenishment planning solution to your processes and maximize value. Unlimited training and iterative solution configuration help future-proof your investment.

Key Replenishment Planning Features

Omnichannel Order Accuracy

Allocate the right product quantities to the right locations with high precision. Algo enhances your ability to meet localized customer demand across all sales channels. Dynamically adjust replenishment based on a wide range of factors, including promotions, supply chain disruption, store count adjustments, and more.

Constrained Lifecycle Planning

Achieve the greatest possible return on limited product quantities. Algo's replenishment planning software streamlines the launch of new products by providing recommendations based on the performance similar items. Optimize and automate replenishment for everyday items that are in limited supply. Optimize your selldown strategy by ensuring end-of-life items are in the best stores.

Embedded Advanced Analytics

Make better orders and allocations using accurate and granular information on planograms and inventory. Algo's replenishment planning solution uses factors like historical sales, open-to-buy, seasonality, and placement minimums to create plans for new and existing items. Our clustering capabilities simplify allocation at the item-location level by creating groups of similarly performing stores.

Collaborative Replenishment Planning

Spend less time explaining your numbers across manual spreadsheets and focus on creating the best possible allocation and replenishment plans. A shared view of all inventory and planogram information enables highly productive, real-time collaboration on replenishment plans. Algo’s single version of the truth minimizes errors, delays, and business risk.

Data Integration and Aggregation

Algo’s 90+ pre-built integrations unify data from enterprise applications, open-source platforms, and other data sources from across your supply chain. Our data aggregation and cleansing ensure that your replenishment decisions are always informed by accurate and complete information on planograms, orders, and inventory.

Results and outcomes

Clients using Algo’s software typically observe marked improvements in operational efficiency and a streamlined pathway towards growth, thanks to better-informed strategic decisions. These enhancements are pivotal in elevating overall customer satisfaction and driving sales growth.

Allocate right. Stay in sync.

Plan replenishment at scale.