Decision Intelligence Across Your Supply Chain

Praise from our valued customers

“When we started work with Algo we were hoping for better visibility into what was happening in our channel – what we got was real time understanding, analytics, anomaly detection and for the first time a predictive perspective. Algo not only listened, they took our feedback, understood our pain points and then turned that into actionable insights. Algo helped us turn a problem into an opportunity in one of the toughest times for Supply Chain globally.”

David Warrick

Former Global Supply Chain General Manager & Innovation Officer at Microsoft

Results and outcomes

Clients using Algo’s software typically observe marked improvements in operational efficiency and a streamlined pathway towards growth, thanks to better-informed strategic decisions. These enhancements are pivotal in elevating overall customer satisfaction and driving sales growth.

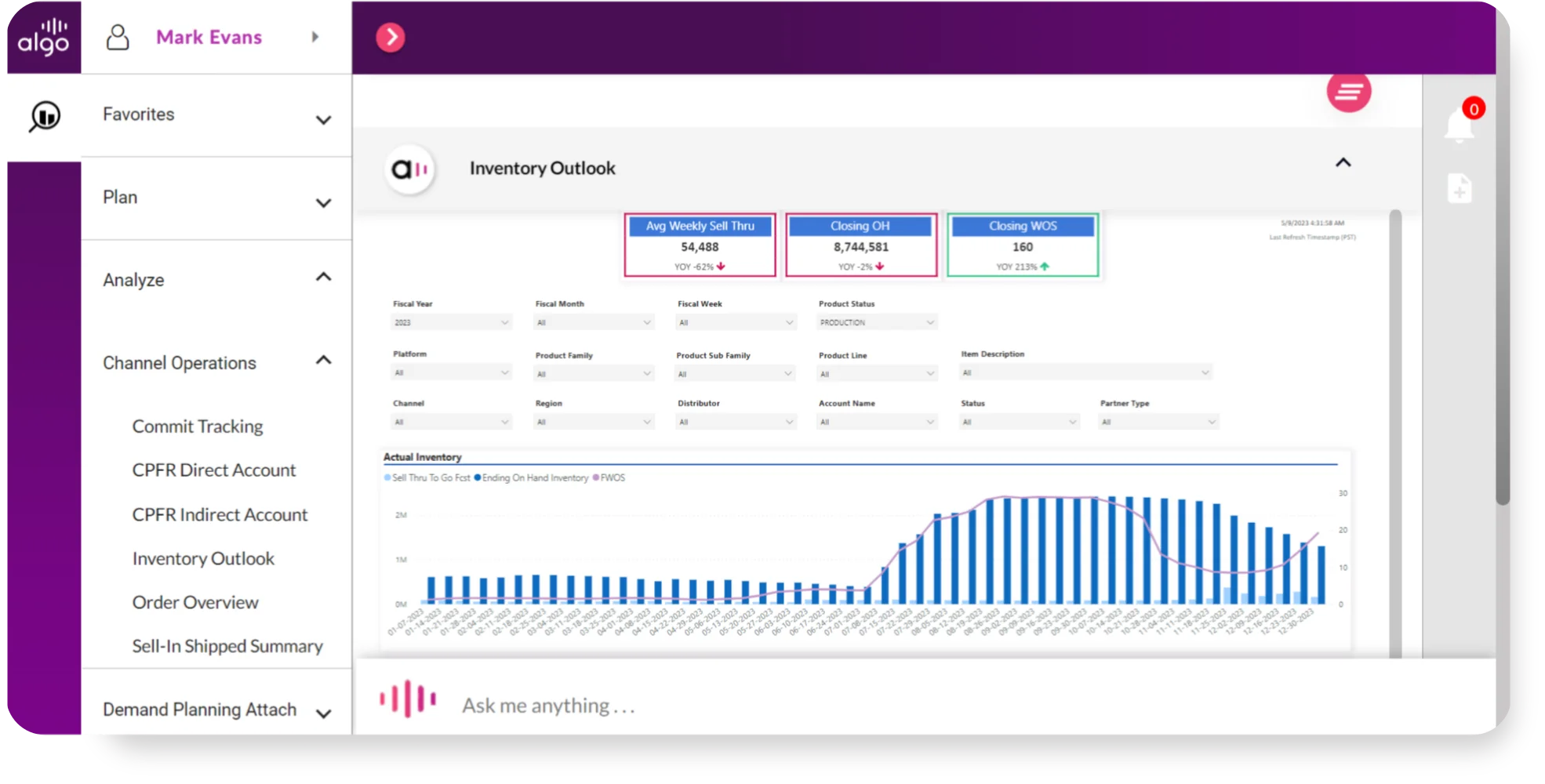

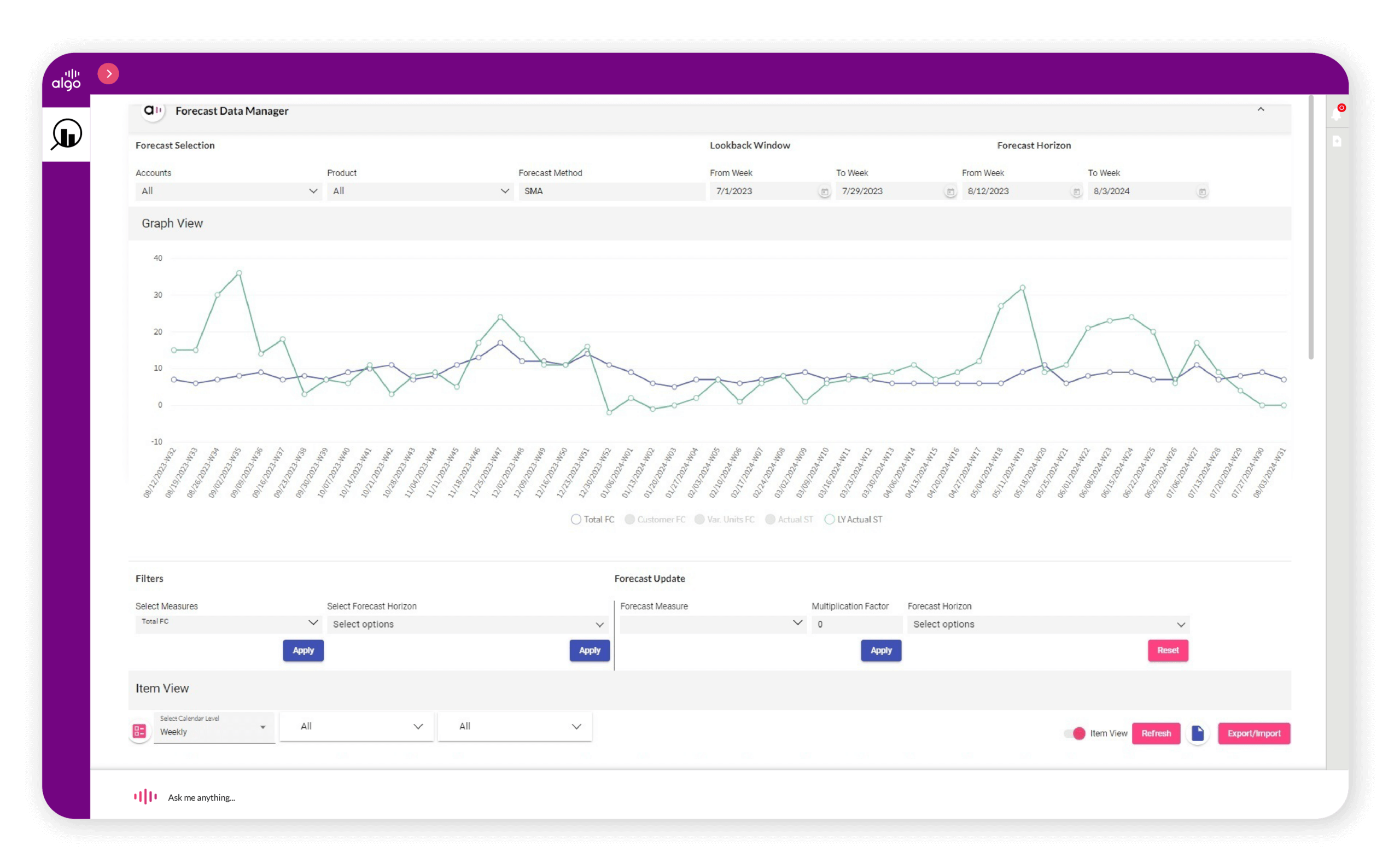

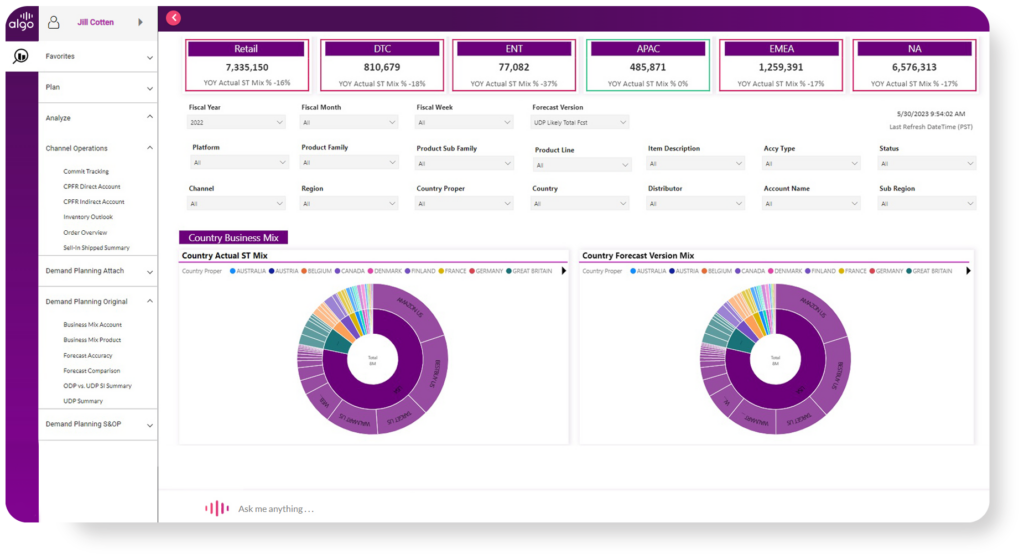

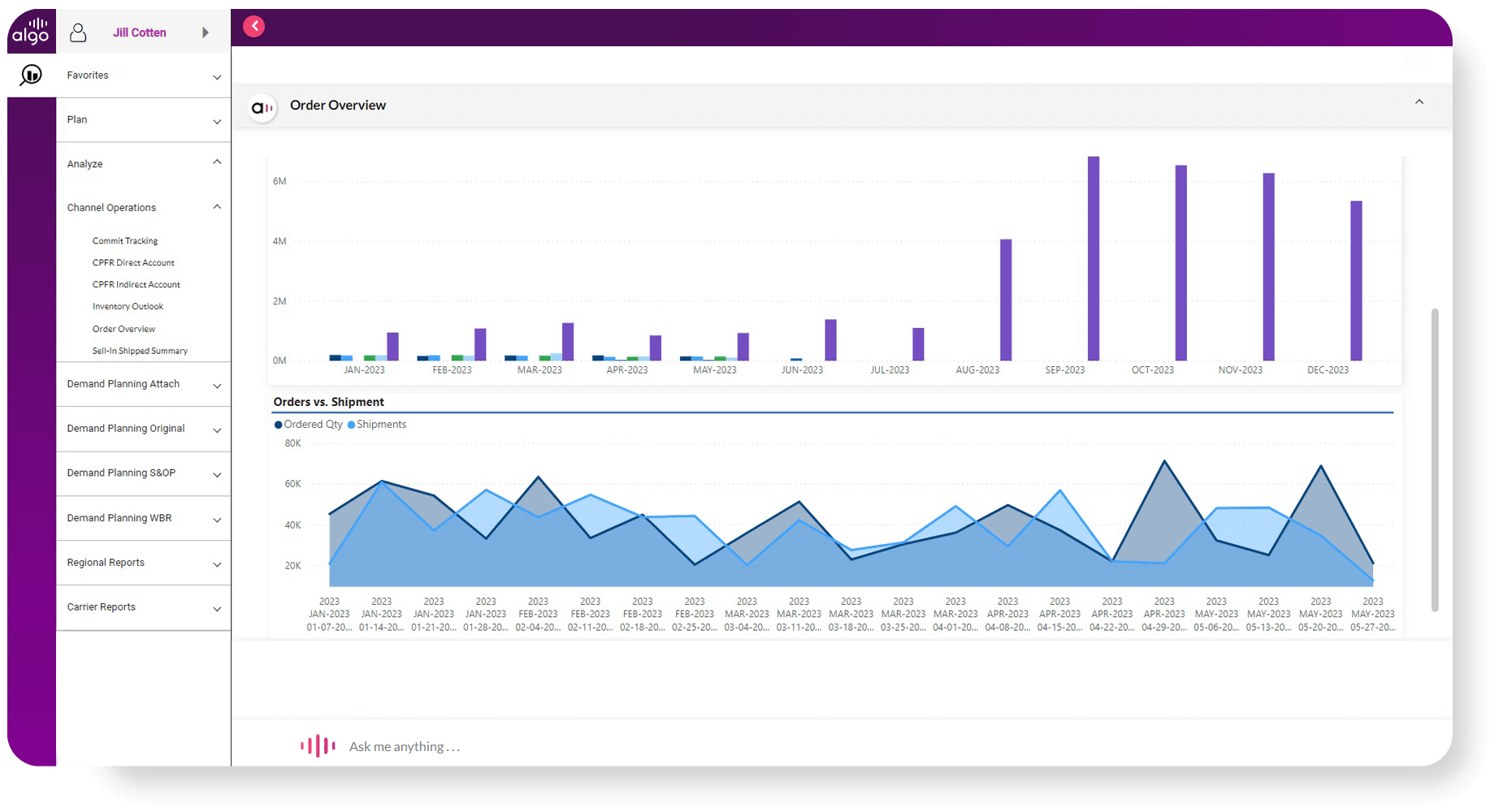

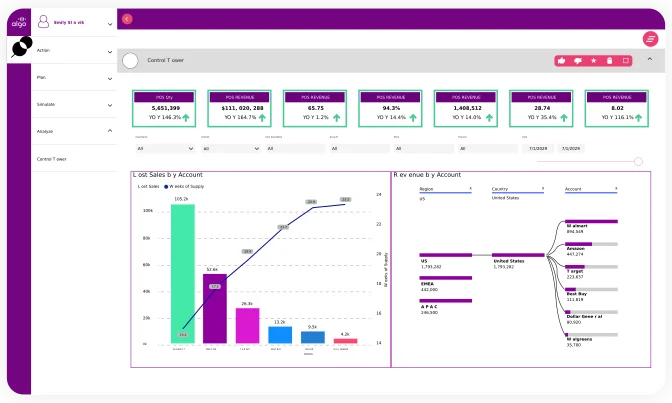

Empower Your Supply Chain with Complete Visibility

Learn how to navigate your supply chain journey with a consolidated, bird’s eye view of the entire chain. Book now and monitor inventory across every level, optimize, and respond – all within Algo’s Control Tower.