Key Features

Forecasting

Anomaly Detection

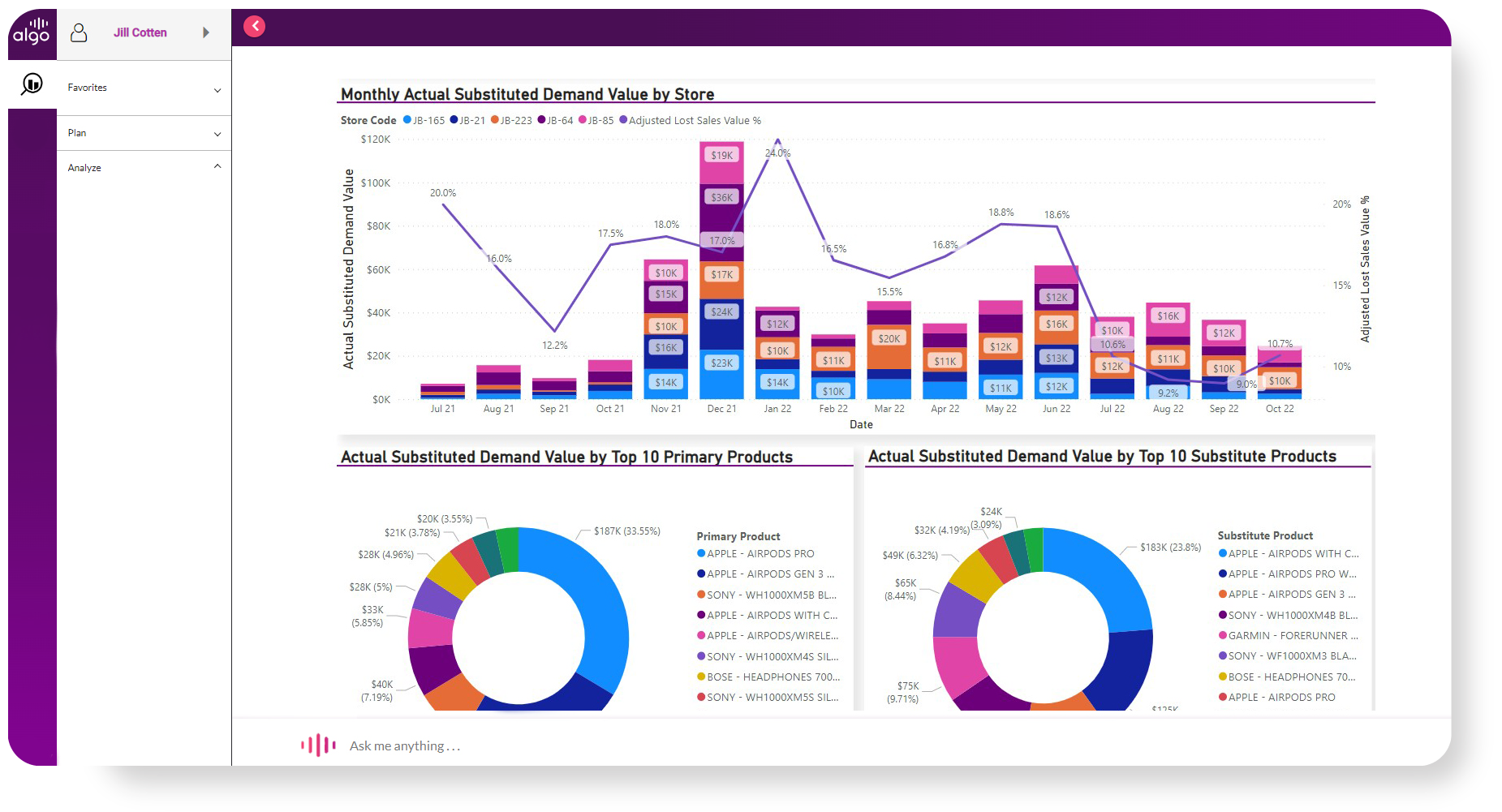

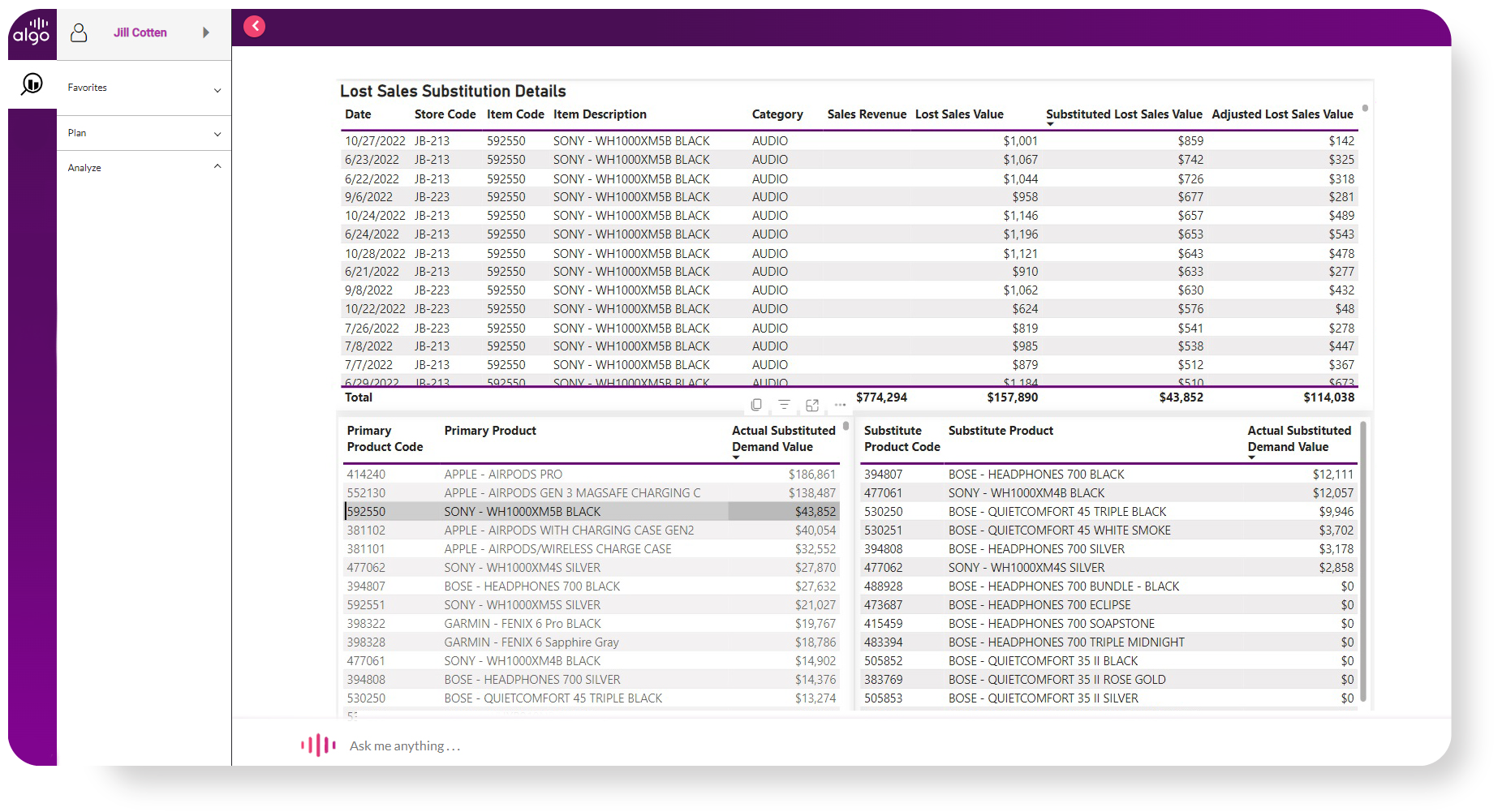

Demand Substitution

Why Choose Algo’s Lost Sales Optimizer?

Understand your lost sales, optimize your inventory levels, and seize every sales opportunity. Choose Algo Lost Sales Optimizer and drive better business outcomes.