Demand forecasting is all about looking at past data and understanding external factors to predict future demand.

By doing so, businesses can plan their supply chains more effectively, deciding when to restock, how much capacity to allocate, and how to use resources wisely. But if forecasts go wrong, it can lead to too much stock, stockouts, or wasted resources, which directly impacts profits and customer satisfaction.

Forecasts aren’t all the same. For short-term needs like perishables, forecasts tend to be more detailed, usually done on an hourly or daily basis. But for products that are more stable, like long-lasting items, forecasts are usually made monthly or quarterly.

Traditional forecasting methods often rely on manual processes and siloed data, making it hard to keep up with fast changes in demand. These methods also struggle to account for factors like weather, marketing, and unexpected events. Recent disruptions, like the pandemic, have shown just how crucial it is to move toward data-driven, adaptive forecasting.

So, what is DFS? A smarter way to forecast demand

Demand Forecasting as a Service (DFS) gives businesses access to advanced forecasting tools powered by AI and machine learning.

Instead of creating and managing their own forecasting engine, businesses can simply upload their historical data to a managed platform, which then returns the forecasts. This setup removes the need for complicated infrastructure and in-house data science teams, making high-end forecasting more accessible.

DFS lets businesses skip the tech-heavy parts of forecasting and rely on pre-built machine learning models that are constantly updated and maintained by the provider. All users have to do is provide the data and interpret the results, freeing up internal teams to focus on bigger-picture tasks.

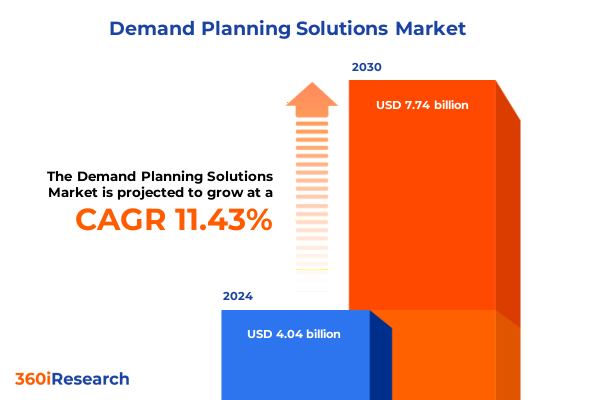

Demand planning solutions are projected to grow at 11.43% CAGR to $7.74B by 2030—a clear tailwind for DFS adoption. (Source: 360iResearch)

The beauty of DFS is its simplicity. The service typically starts with a scoping exercise to understand your needs, followed by a proof of concept, and then full deployment. Plus, the cloud-based setup means businesses can scale as needed—making it easy for smaller companies to use enterprise-level tools without huge upfront costs.

How DFS works: The simple, straightforward process

Here’s how DFS works from start to finish:

- Getting Started (Scoping): First, we take a close look at your current forecasting methods, the metrics you’re using (like MAPE), and your goals. We define the scope—whether that’s forecasting demand for top products over a short period or creating longer-term predictions. Historical data is provided, and don’t worry, it can be anonymized and encrypted for security.

- Going Live (Production Deployment): Once the groundwork is laid, we move into full production. The data is securely uploaded, and the AI/ML pipeline starts generating forecasts. These forecasts are delivered back to you via secure storage, ready for your team to use in planning and decision-making.

- Always Improving (Continuous Improvement): DFS isn’t a set-it-and-forget-it system. As you provide feedback and as AI learns from new data, the model is constantly refined. This continuous feedback loop ensures forecasts stay accurate and relevant as market conditions evolve, reducing any drift in predictions over time.

The tech that makes DFS work: AI and cloud power

DFS is built on powerful AI and machine learning technologies that make it possible to process huge amounts of data and spot patterns that traditional methods might miss. Here’s how the technology behind it works:

- AI and Machine Learning Models: These algorithms are designed to automatically improve forecasting accuracy by learning from vast amounts of data. The beauty of machine learning is its ability to recognize hidden patterns and trends that humans would often overlook. Plus, it automates much of the forecasting process, saving time and minimizing errors.

- Incorporating More Data: DFS doesn’t just rely on sales data. It pulls in external data—things like pricing, marketing calendars, weather data, and even social media signals. This extra data helps create more accurate forecasts by capturing the bigger picture.

- Cloud Infrastructure: DFS runs on scalable cloud platforms, which means you don’t need to invest in costly infrastructure or hire a team of data scientists. Everything is hosted in the cloud, allowing businesses of all sizes to benefit from cutting-edge forecasting technology without the heavy lifting.

Why DFS is a game changer: The key benefits

DFS offers a ton of benefits that help businesses improve their forecasting and run their supply chains more smoothly:

- Smarter Inventory Management: By accurately predicting demand, DFS helps businesses keep the right amount of stock at the right time. This reduces the risk of overstocking or stockouts, keeping customers happy and operations efficient.

- Optimizing Prices and Promotions: Combining demand forecasting with pricing strategies allows businesses to see how price changes might affect demand. This helps category managers plan promotions and set prices in a way that boosts both sales volume and revenue.

- Quick, Easy Implementation: Because DFS is cloud-based, it’s easy to set up. Unlike traditional solutions that can take months to implement, DFS can deliver results in just a few weeks, giving businesses a fast return on investment.

- Boosting Revenue: AI-driven demand forecasting can lead to a 3–4% increase in revenue by ensuring better product availability, reducing lead times, and aligning stock with demand.

- Cutting Costs: Precise forecasting helps businesses optimize inventory, reducing excess stock and cutting down on waste and handling costs. The result? Lower operating expenses and a healthier bottom line.

- Accessible for Mid-Market Companies: DFS isn’t just for the big players. Thanks to cloud-based tools, mid-sized companies can now access the same high-quality forecasting services that were once reserved for large enterprises. This levels the playing field and gives smaller businesses the ability to predict demand just as accurately.

Real-world applications of DFS

DFS is versatile and can be applied across a variety of industries. Here’s how it helps in different sectors:

- Retail and CPG: Retailers and CPG category managers use DFS to optimize stock levels, plan promotions, and adjust assortments. With accurate demand predictions, businesses can ensure they have the right products in the right stores at the right time, maximizing sales and minimizing waste.

- Manufacturing: Manufacturers can combine retail data with raw-material needs to create accurate forecasts that optimize bulk purchasing and production planning. This leads to better decision-making and more efficient use of resources.

- Supply Chain Planning: DFS helps businesses forecast demand across regions, product lines, and echelons, making it easier to plan for sourcing, production, and capacity. This ensures businesses allocate resources efficiently, keeping supply chains running smoothly.

- Inventory Management and Logistics: For businesses in sectors like electrical and consumer electronics, DFS helps manage slow-moving stock and minimize the impact of aged models. It also ensures data is securely transferred, reducing issues with obsolete products and optimizing inventory levels.

Things to keep in mind when adopting DFS

As with any new technology, there are a few key considerations when adopting DFS:

- Data Quality and Integration: To get the best results, your data needs to be clean and comprehensive. You’ll also need to integrate data from different sources—like ERP systems, POS, and external data—to make sure your forecasts are as accurate as possible.

- Aligning Metrics: Before implementing DFS, set clear goals. Whether it’s improving forecasting accuracy (MAPE), reducing returns, or boosting sales, having defined metrics from the start ensures the system aligns with your business objectives.

- Managing Change: Transitioning to DFS will likely require a shift in mindset. Planners must trust the machine-generated forecasts, so transparency and understanding of the AI models (like how transformer-based models work) will help build confidence.

- Choosing the Right Vendor: When selecting a DFS provider, consider factors like forecast accuracy, scalability, integration ease, support, and data governance. Picking the right provider ensures that the system will meet your needs and scale with your business.

How to get started with DFS

Adopting DFS doesn’t have to be complex. Here’s a roadmap to help guide your journey:

- Assess Readiness: Start by auditing your current processes and identifying pain points. Understand where your forecasting falls short and what needs to be improved.

- Define Your Goals: Set clear, measurable objectives before you start. Whether it’s reducing MAPE or decreasing stockouts, having these goals in place will help ensure a smooth transition.

- Try It Out (PoC): Select a provider and run a proof of concept (PoC) with a small group of SKUs. This lets you test the system and make sure it meets your needs before scaling.

- Refine and Improve: Compare the DFS forecasts with your baseline data and refine the inputs, metrics, and parameters to improve accuracy.

- Scale to Full Production: Once the PoC is validated, integrate DFS into your planning systems and automate data transfer. This makes forecasting a seamless part of your daily operations.

- Monitor and Optimize: Continuously track the system’s performance, gather feedback, and make adjustments. Add new data sources as needed to further improve accuracy.

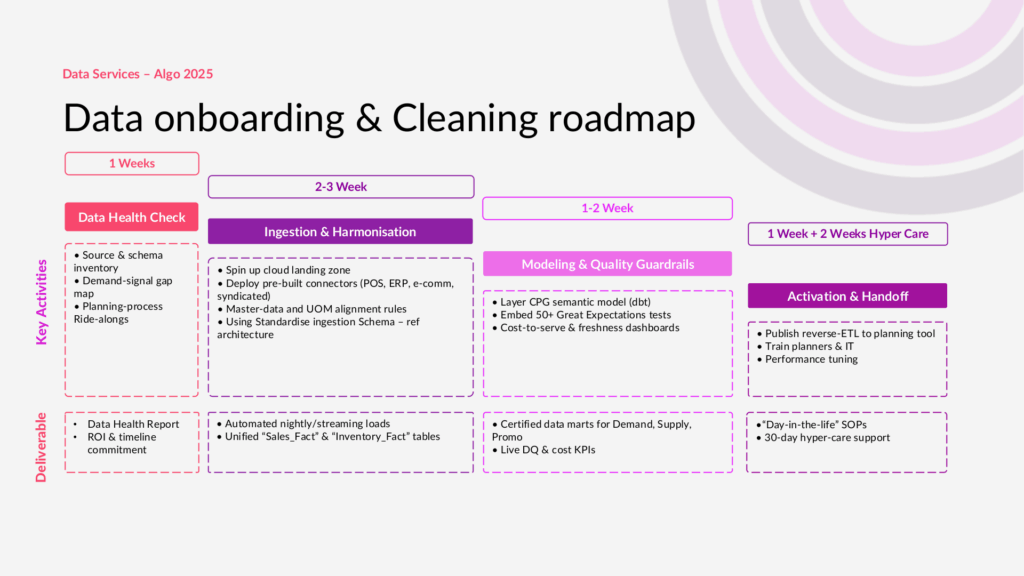

Algo’s data onboarding & cleaning roadmap: from messy to forecast-ready in weeks.

Looking ahead: The future of DFS

The future of DFS is bright, with several exciting trends shaping the landscape:

- More Interpretable and Multi-Horizon Models: As AI continues to advance, we can expect more interpretable models that offer clearer insights into how forecasts are made. These models will be more transparent, helping businesses understand the reasoning behind predictions.

- Autonomous Supply Chains: In the future, AI will handle much more than just forecasting. Autonomous supply chains will rely on AI to manage forecasting, planning, and execution, with minimal human input.

- Integration with Digital Twins: DFS will increasingly be combined with digital twins, enabling businesses to simulate their supply chains and test scenarios before making decisions.

- Democratising Forecasting for SMBs: As the cost of AI-driven solutions drops and usability improves, smaller businesses will gain access to enterprise-level forecasting tools, leveling the playing field and opening up new opportunities.

Conclusion

Demand Forecasting as a Service (DFS) offers businesses a powerful, scalable solution for optimizing forecasting and improving supply chain operations. By leveraging AI and machine learning, DFS delivers accurate, data-driven insights that help businesses streamline inventory management, optimize pricing, and make smarter decisions across the supply chain. As these technologies continue to evolve, DFS will remain a key driver of business success, offering long-term value and growth opportunities.

About the author

Karen McNaughton

Karen is the Vice President of Global Marketing at Algo, where she leads strategies to enhance brand awareness and demand generation for the company’s supply chain intelligence platform. With over twenty years of experience in senior marketing roles at various SaaS technology organizations, Karen brings extensive expertise in leading global marketing teams and executing go-to-market strategies.