Retail Supply Chain Software for Smarter, Faster Decision-Making

Whether you need an end-to-end demand planning solution for retail or targeted solutions like demand forecasting, inventory optimization, or pricing strategies—Algo delivers rapid implementation, ensuring you achieve faster time-to-value with measurable results.

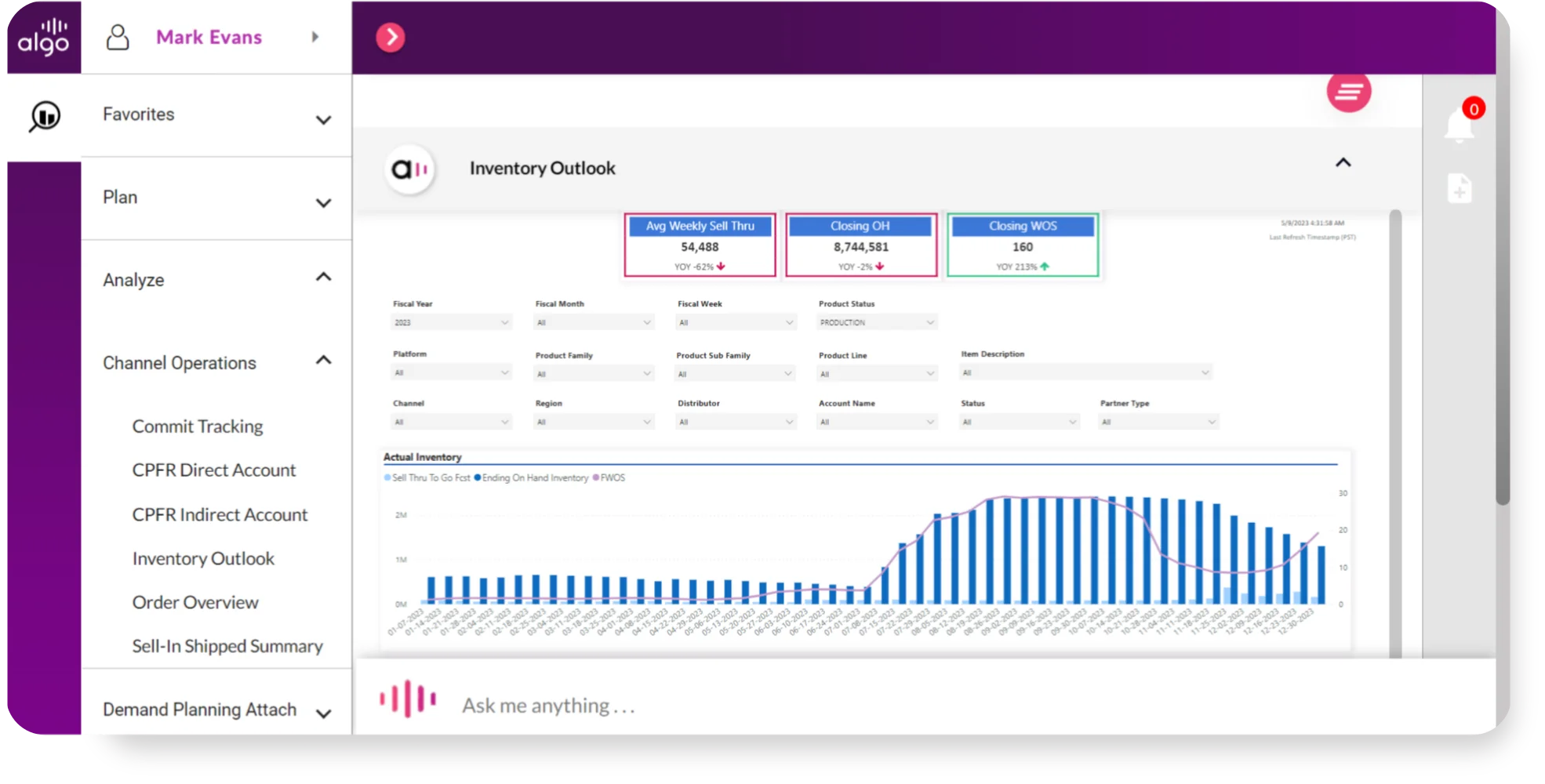

Unlock Retail Insights Instantly with GenBI — No Queries, Just Smarter Decisions

Demand Planning Challenges faced by Retail Supply Chains

Poor inventory management ties up capital, increases markdowns, and weakens profitability for hard goods retailers. Maintaining the right stock balance requires real-time visibility and precise demand planning to minimize waste, reduce lost sales, and optimize margins.

The Cost of Aged & Obsolete Inventory

Outdated or redundant stock ties up capital and leads to heavy markdowns. Hard goods retailers struggle to manage inventory lifecycles, reducing waste and maximizing profitability.

Striking the Right Inventory Balance

Too much stock increases holding costs, while too little weakens the customer offer. Retailers need precise demand planning to maintain an optimal inventory mix without overcommitting.

Reducing Lost Sales from Stock Gaps

Inaccurate inventory visibility leads to missed sales opportunities and poor customer experiences. A real-time, store-level view of stock is critical for managing fluctuations in demand.

Learn how Target Optimized Demand Planning and Retail Product Allocation Across Multiple Categories with Algo

“Target and Algo have expanded on our partnership continuing to build on the strong relationship within the books category. Continuing to leverage the spirit of collaboration across suppliers, Target and Algo, leveraging the Algo system to improve store by product allocations and to partner with Algo to solve business problems and innovation. We are very excited to continue this journey both for locally replenishment and overseas orders as well as expanding across categories from traditional areas like home and toys to apparel, footwear and accessories.”

Nicole Szudja, General Manager of Merchandise, Target

The Algo Benefits for Retailers

Improve Forecast Accuracy & Demand Responsiveness

Algo’s AI-powered demand planning continuously analyzes real-time sales data, market trends, and external factors like seasonality and supply chain disruptions. By refining forecasts dynamically, retailers can anticipate demand shifts, prevent stockouts, and avoid overstocking—ensuring they have the right products available when and where customers need them.

Optimize Inventory & Minimize Excess Stock

With Algo, retailers can maintain optimal stock levels across stores, warehouses, and online channels. The platform intelligently adjusts replenishment and allocation based on demand signals, reducing excess inventory that ties up capital while preventing aged stock from eroding margins. This results in improved sell-through rates and healthier cash flow.

Enhance Pricing & Replenishment Strategies

Algo helps retailers maximize profitability by dynamically adjusting pricing and automating replenishment decisions. AI-driven insights allow businesses to optimize markdown strategies, capitalize on sales opportunities, and maintain strong margins—without sacrificing availability or customer satisfaction.

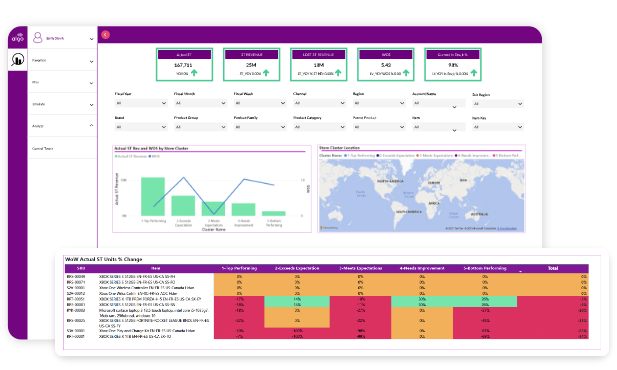

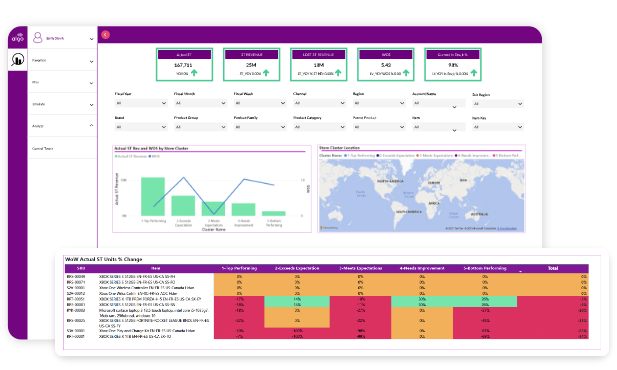

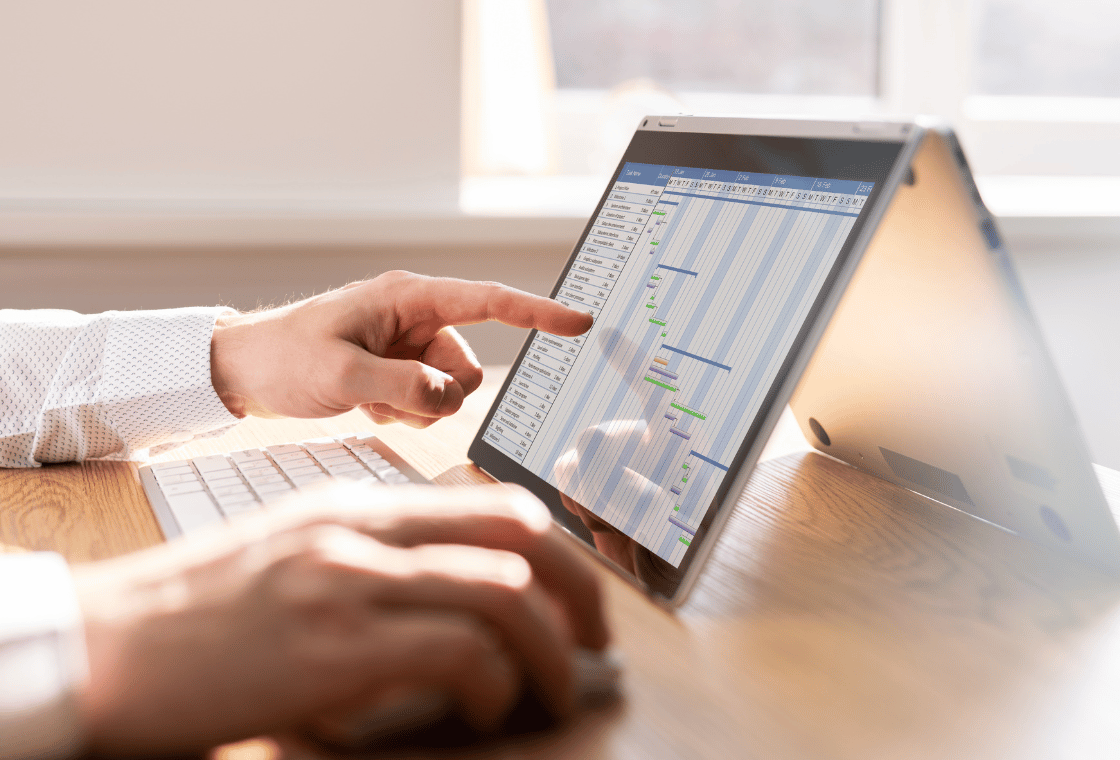

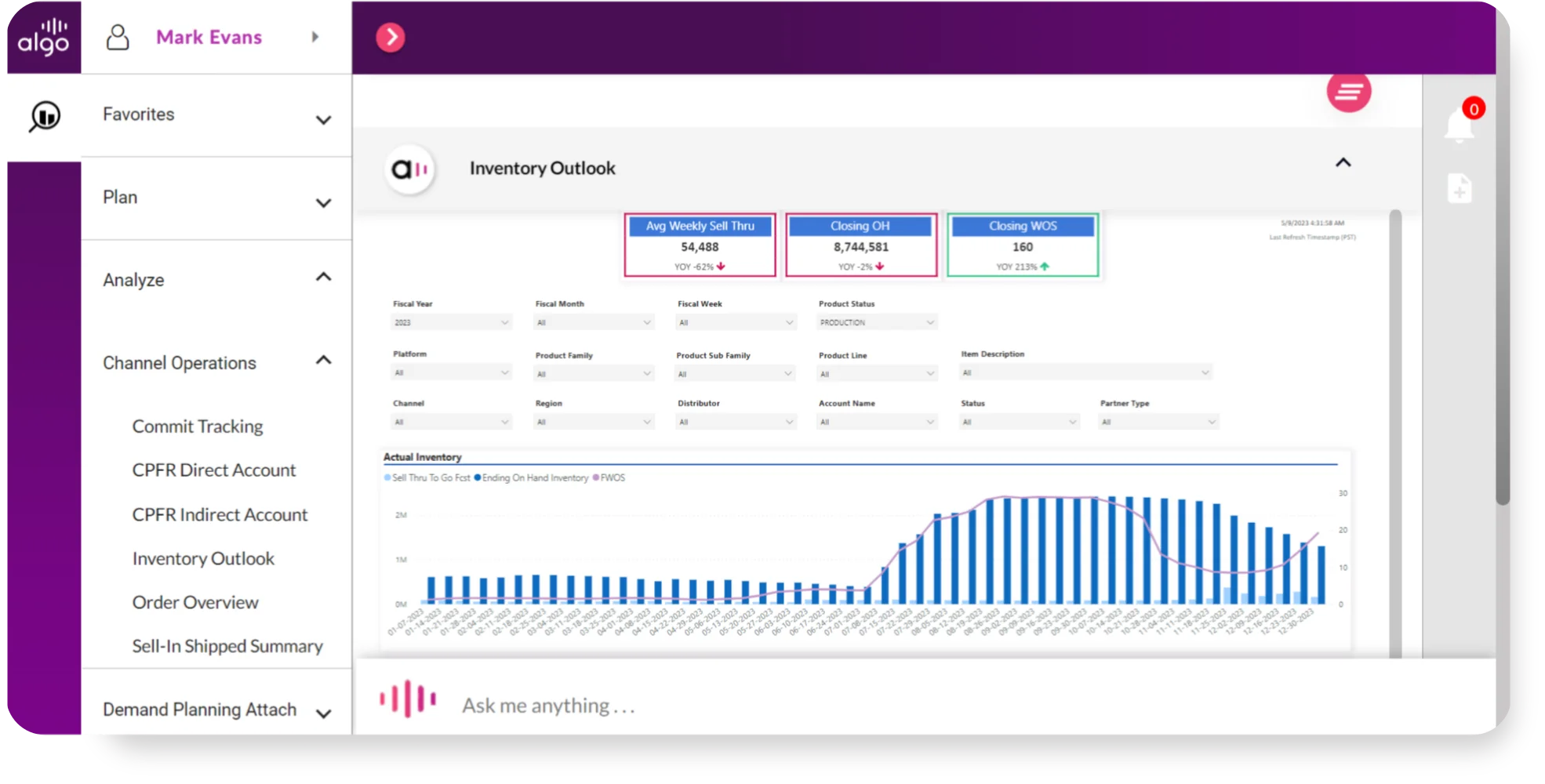

Gain Real-Time Supply Chain Visibility

Algo provides a single, real-time view of demand forecasts, inventory levels, and supplier performance, giving retailers full visibility across their supply chain. By eliminating data silos and enabling proactive decision-making, retailers can quickly respond to demand fluctuations, mitigate supply chain risks, and improve overall operational efficiency.

The Algo Solutions for Retail

Sales & Operations Planning

Synchronize inventory with sales strategies to ensure the right product mix at the right time. Adapt to customer demand, seasonal trends, and promotions with data-driven planning that maximizes sales and enhances the customer experience.

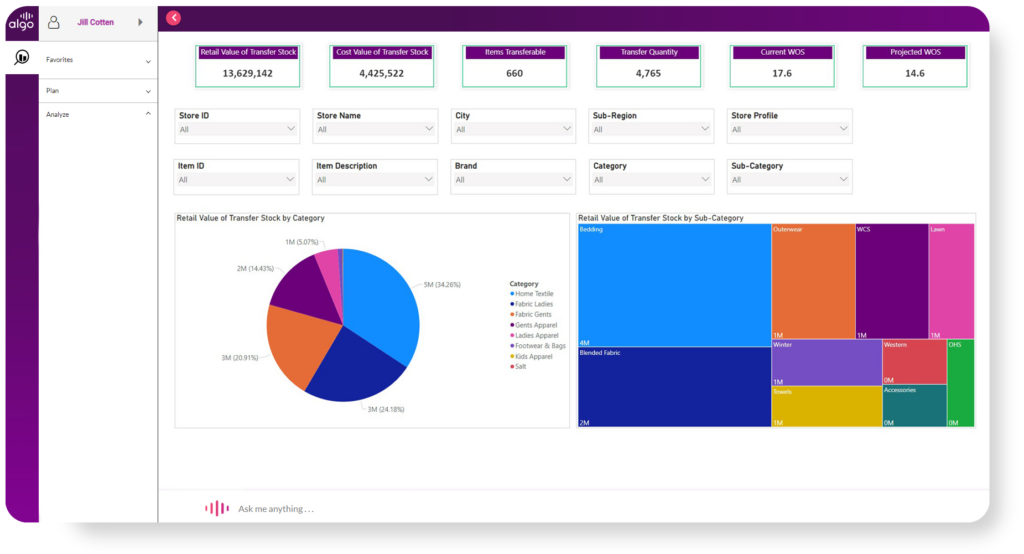

Inventory Optimization

Achieve the perfect balance of supply and demand with real-time inventory insights. Minimize holding costs, prevent stockouts, and maximize profitability through efficient stock allocation and replenishment.

Price Planning

Optimize pricing strategies by aligning product availability with market demand and sales velocity. Reduce stockouts, improve margins, and enhance customer satisfaction with dynamic, data-driven pricing adjustments.

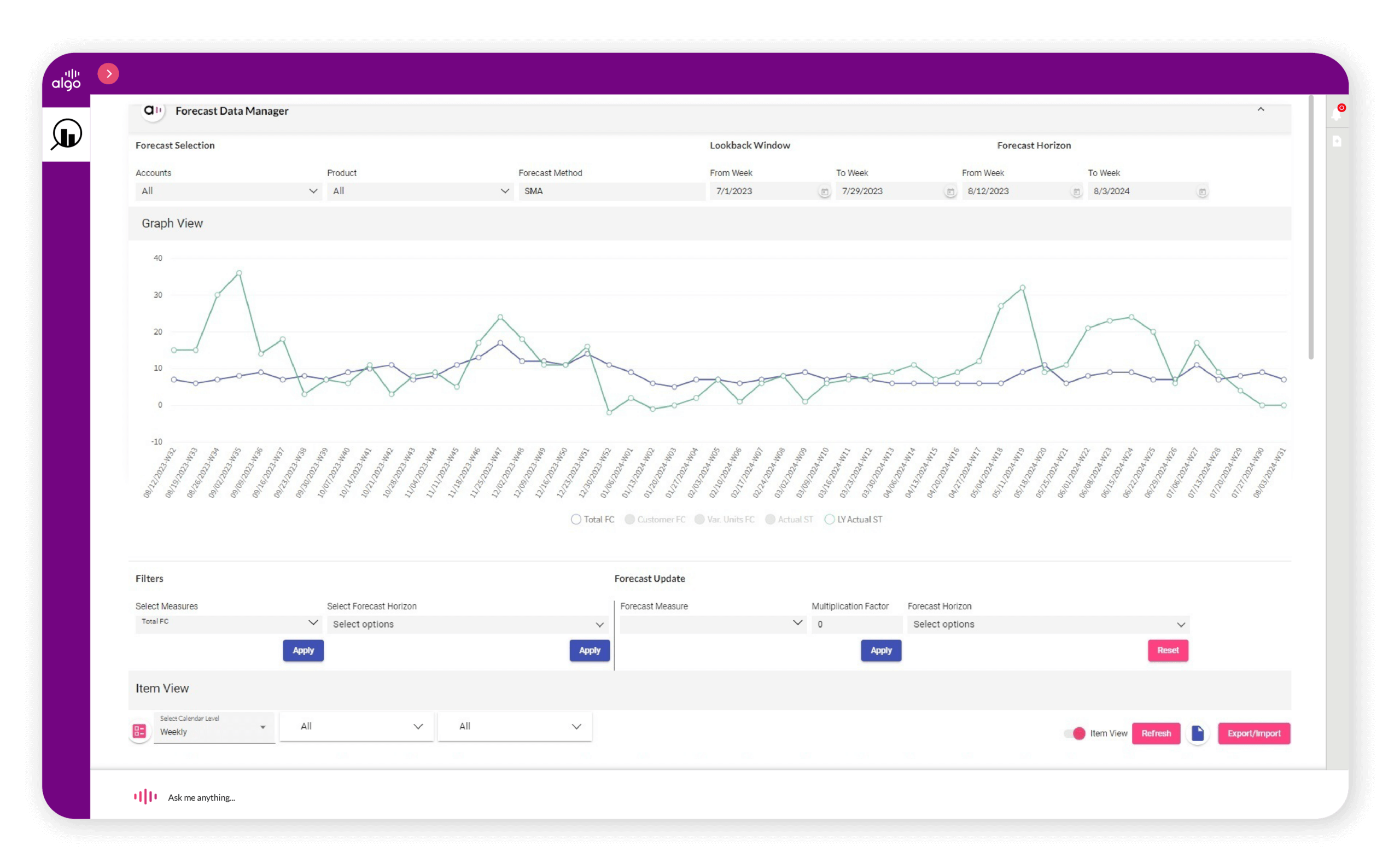

Demand Forecasting

Leverage AI-driven insights to accurately predict customer demand. Optimize stock levels, reduce waste, and ensure products are available when and where customers need them—without the risk of overstocking.

Sales & Operations Planning

Synchronize inventory with sales strategies to ensure the right product mix at the right time. Adapt to customer demand, seasonal trends, and promotions with data-driven planning that maximizes sales and enhances the customer experience.

Inventory Optimization

Achieve the perfect balance of supply and demand with real-time inventory insights. Minimize holding costs, prevent stockouts, and maximize profitability through efficient stock allocation and replenishment.

Price Planning

Optimize pricing strategies by aligning product availability with market demand and sales velocity. Reduce stockouts, improve margins, and enhance customer satisfaction with dynamic, data-driven pricing adjustments.

Demand Forecasting

Leverage AI-driven insights to accurately predict customer demand. Optimize stock levels, reduce waste, and ensure products are available when and where customers need them—without the risk of overstocking.

Why Brands Choose Algo Over Other Solutions

Speed to Value: Go Live in 16 Weeks – Not 12 Months

Enterprise retailers can’t wait a year for results. With Algo, you’re live in 16 weeks—fast, seamless, and disruption-free. Get expert support, optimize sooner, and see ROI faster.

All-Inclusive Implementation: No Third-Party Integrators. No Hidden Costs.

With Algo, what you see is what you get—no extra fees, no external tools, no surprises. Our in-house team handles everything, ensuring a seamless setup without added complexity. One system, one team, one smooth transition.

Ongoing Support & KPI-Based Success: We Don’t Just Deliver Software, We Deliver Results

At Algo, implementation is just the beginning—we provide ongoing support to ensure your success. Our team tracks key performance indicators (KPIs), refines strategies, and continuously optimizes results. Unlike providers that leave you on your own, we offer hands-on support, expert insights, and proactive recommendations to keep your business ahead.

Algo’s Next Evolution: Generative Business Intelligence

What if your retail supply chain didn’t just react to past sales but anticipated demand and optimized inventory in real-time? With Algo’s Generative Business Intelligence (Gen BI), you can interact with your data using natural language, eliminating complex queries and making powerful insights accessible to your entire retail team—from store managers to supply chain executives.