Why Inventory Optimization Matters

Inventory isn’t just a cost — it’s a competitive advantage if optimized right. But legacy systems, manual planning,

and rigid rules-based setups can’t keep pace with today’s volatile retail landscape.

How Algo’s inventory optimization software works

Turn Smarter Optimization into Faster Results

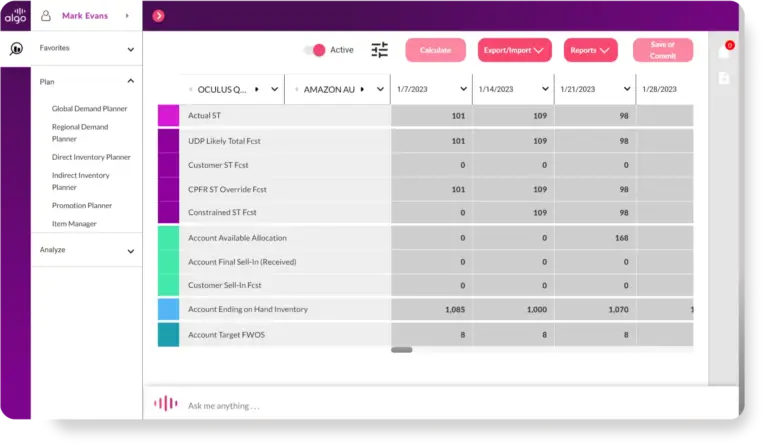

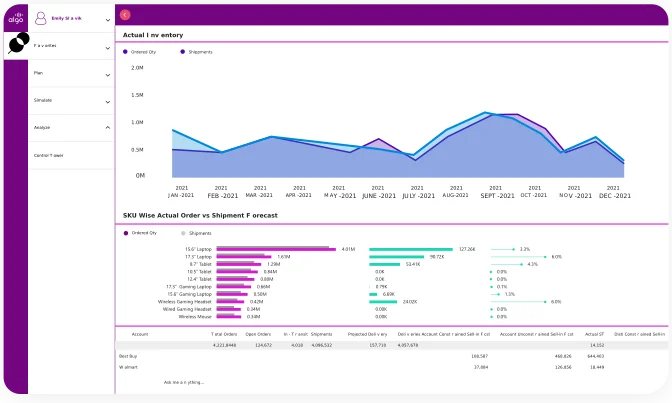

Go beyond optimization with GenBI

Understand the why behind every inventory decision — instantly. Algo’s GenBI empowers your team to ask questions in plain English and uncover insights into stock movements, service levels, supplier risks, and optimization strategies. No technical skills required — just faster, smarter decision-making powered by generative AI.

- Natural Language Inventory Queries: Eliminate complex reporting workflows by simply asking questions like “Where are we at risk of stockouts next week?” or “Which suppliers are impacting service levels?” — and get immediate, actionable answers.

- Real-Time Inventory Adjustments: Receive AI-powered recommendations that dynamically adapt replenishment and stocking strategies to market shifts, supplier disruptions, and demand fluctuations.

- Context-Rich Visualizations: Spot trends, risks, and anomalies quickly with visual dashboards tailored specifically for retail inventory performance — from SKU-level views to network-wide insights.

- Faster Time to Impact: Deploy within weeks and start driving smarter, faster inventory decisions — without waiting for complex BI tool integrations or custom development.

- Unified Decision-Making Across Teams: Empower sales, marketing, operations, and supply chain teams to collaborate with shared, easily accessible insights — breaking down silos and aligning inventory strategies to business goals.

Why Brands Choose Algo Over Other Solutions

Speed to Value: Go Live in 16 Weeks — Proven, Predictable Rollout

Enterprise retailers can’t wait a year for results. With Algo, you’re live in 16 weeks—fast, seamless, and disruption-free. Get expert support, optimize sooner, and see ROI faster.

All-Inclusive Implementation: No Third-Party Integrators. No Hidden Costs.

With Algo, what you see is what you get—no extra fees, no external tools, no surprises. Our in-house team handles everything, ensuring a seamless setup without added complexity. One system, one team, one smooth transition.

Ongoing Support & KPI-Based Success: We Don’t Just Deliver Software, We Deliver Results

We provide ongoing, hands-on support—tracking KPIs, refining strategies, and optimizing performance. Unlike providers that leave you on your own, we deliver expert insights and proactive guidance to keep your business ahead.

Endorsement from an Industry Leader

“Working with Algo for the last 15 years has safeguarded a healthy, efficient and viable footprint with key business partners across our physical formats, ensuring we have the right products, in the right place, at the right time, and reduced out-of-stocks and obsolescence issues dramatically.

Sean Warner

President and CEO of Universal Music Group – Australia and New Zealand